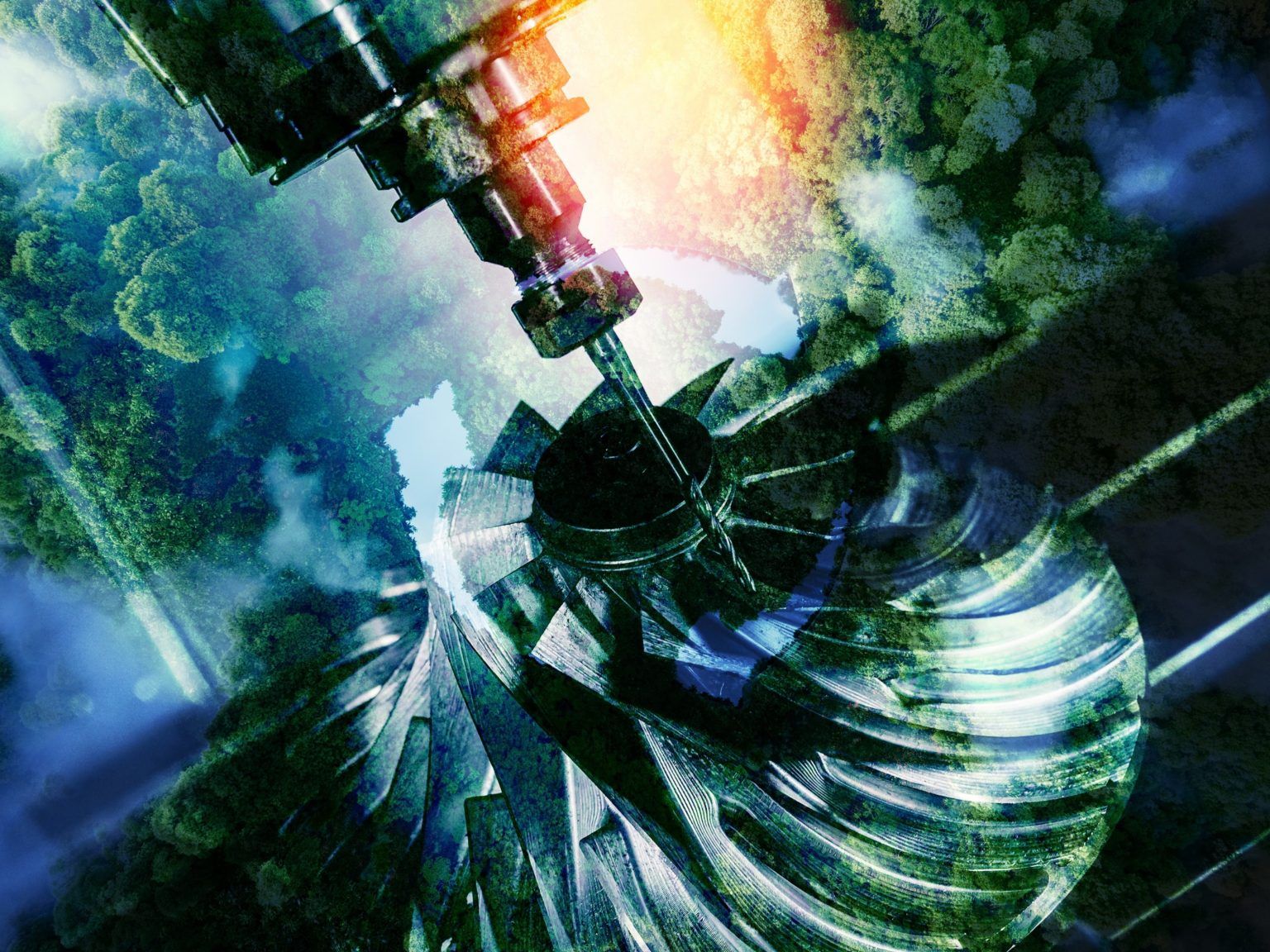

Checklist: How to Automate Milling Machine Tools

How to Prepare Your Facility for Automation.

Increasing spindle utilization and lights-out manufacturing; minimizing lead times and scrap; offering safe, ergonomic and interesting jobs…everyone has a reason to automate. The real question is: how to automate? Here is our practical checklist for automating milling machining centers, based on over 5,000 automation projects for over 90 machine tool brands. https://www.fastems.com/blog/checklist-how-to-automate-milling-machine-tools/

1. How to Ensure Your Machine Tool Can Be Automated?

The first step is to ensure your machining center has a suitable design and configuration for automation. As long as the following conditions are met, you technically can – and from the economical point should – automate your machine tool.

2. How to Match Automation with Your Production Mix?

The second and most important factor for a successful automation project are your actual manufacturing needs – the production mix, volume, lead times, manufacturing phases, etc.

3. How to Prepare Your Facility for Automation?

The third important factor for automation is the actual production facility. The physical dimensions, layout and surrounding processes all play a large role when selecting and configuring machining automation.

- Fastems AB - Stenungsund

- https://www.fastems.com/

- Företagsprofil

- 0303-246 900

- E-post